Knocked out the other two this morning. Summarizing the experience since I came across some confusing info out there. 12567085 was the PN for my 06 for the replacement magnets.

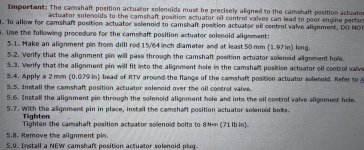

Official procedure (attached photo) is to take out the black center cap on the magnet and use a 15/64" dowel rod in there as the centering device. However, removal of those center caps destroys them and I can't even find a part number [edit: PN is 12567421 and it's discontinued & unavailable], nor a listing for them. So I didn't want to remove those caps and use the centering pin. On to Plan B, the three studs method.

I used Hillman 880660, cut the heads off, and wrapped two layers of vinyl tape around the upper two thirds of them (so it was a tight fit passing them through the bolt holes on the magnets). To remove the old magnets, I backed out each of the fasteners until I could see about 1mm of exposed thread, then used a sharpened chisel to break the seal. Once the magnet was free for that 1mm of play, removed the fasteners one at a time, replacing them with the studs. Remove old magnet, use sharpened plastic chisel to remove the adhesive/sealant down to bare metal, vacuum out the bits of debris, use extreme care not to get any in the center opening or on the VVT actuator itself. Cleaned mating surfaces of new magnet and on the engine with brake clean and lint free rag. 2mm bead of black rtv on the new magnet. Install (using the studs to align it properly). One at a time, remove studs and replace with fasteners, hand tightened. Wait one hour, torque to 8Nm.

Since my connectors were oily, I used QD electronic parts cleaner and cleaned them out as best I could, let them dry, reassembled. In my case, doing this job with the PS reservoir removed, as well as the alternator/water pump belt & tensioner removed, gave me plenty of clearance to work.